CAPABILITIES

Tri Valley Hose houses the capabilities you need for quality industrial, hydraulic, and automotive hose assemblies. Our quality hose components are assembled by our experienced staff as per your requirements. We offer priority counter service for prompt solutions for your hose needs. We crimp hose up to 4” diameter for industrial applications such as petroleum & chemical. Our hydraulic crimpers can attached fittings for safe operation in high pressure fluid power uses. With Tri Valley Hose’s automotive hose capabilities, you can save significantly over dealer and repair shop prices! Browse our capabilities below, and contact us today for superior hose service!

HOSE CRIMPING

HYDRAULIC

Tri Valley Hose offers hydraulic hose assemblies up to 2” inside diameter and hoses capable of transferring fluid at 10,000 psi. Our experienced technicians will build your hose from the finest components and crimp to factory specifications.

INDUSTRIAL

With the capability to crimp hoses up to 4” inside diameter, Tri Valley Hose can assemble & fit hoses for industrial applications such as air & water, chemical, petroleum, and more. Our Uniflex S10 crimper gets the job done.

MOBILE HOSE SERVICE

ON-SITE SERVICE!

Let us come to you! Our mobile service truck will arrive at your location with an experienced hose technician ready to address your hydraulic hose needs up to 2” ID 4-wire hose!

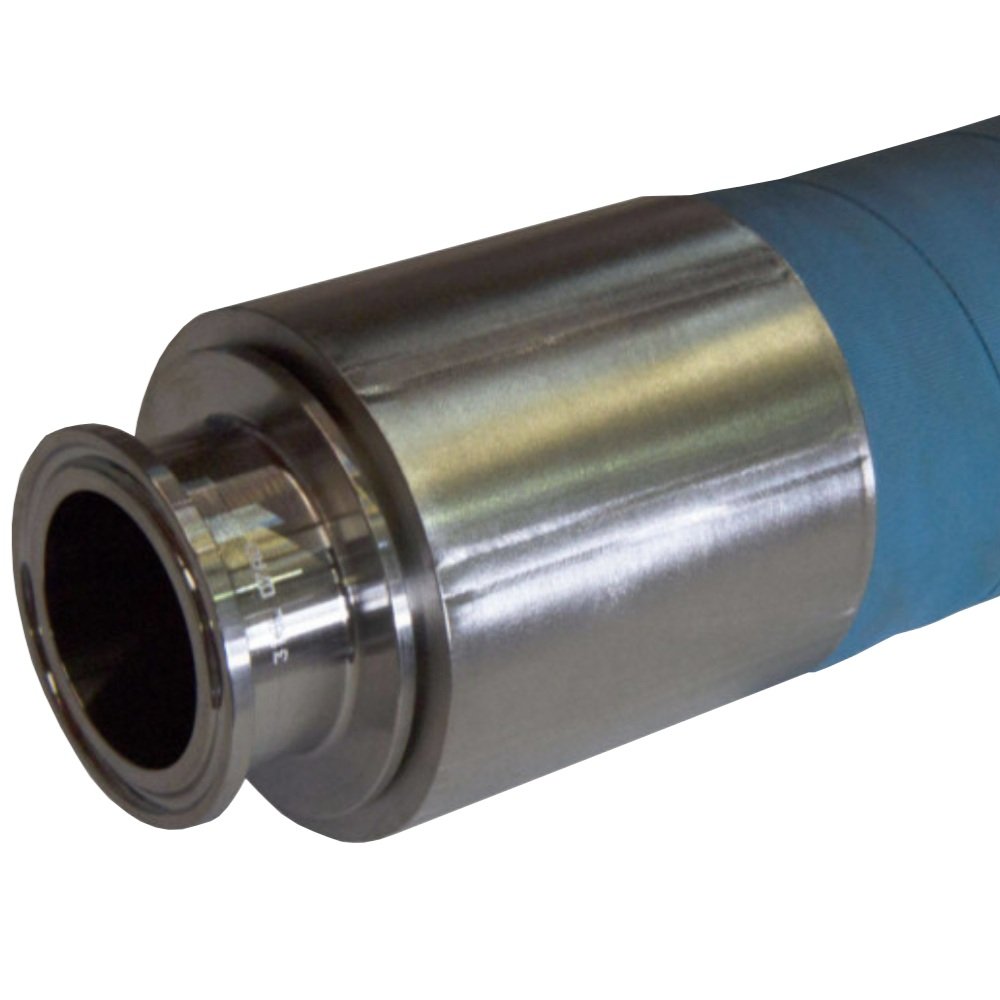

INTERNAL EXPANSION

INDUSTRIAL

Tri Valley Hose can use internal expansion to couple industrial hoses for applications such as concrete, fuel, sanitary, and more.

FIRE HOSE

We custom assemble fire hose so you have access to more than just off-the-shelf products. Customize your lengths & fittings for your needs.

METAL TUBING

TUBE BENDING

With trusty Olsen tube bending equipment, Tri Valley Hose can custom manipulate stainless steel tubing to match your existing sample or prototype application.

AUTOMOTIVE

Custom tubes can be fitted or combined with elastomeric tubing or hose to make automotive hoses such as power steering lines.

WELD & BRAZE

Some applications require a process that safely provides a strong fusion. Tri Valley Hose uses brazing & welding (MIG & TIG) to attached fittings to tubing.

TESTING

HYDRO TESTING

Tri Valley Hose tests hose assemblies up to 5000 PSI and can provide tagging & certification per your requirements!

ULTRA CLEANING

HOSE CLEANING

Tri Valley Hose cleans our assemblies with Ultra Clean technology. This system uses a cleaning projectile, which is shot thru the hose prior to delivery. The projectile removed dirt & particulate that can harm your fluid power system. Save time & money and avoid headaches with Ultra Clean hose.

CLEAN SEALING

Keep your hoses clean and free of contamination with easy-peel, heat shrink seals by Ultra Clean. From the time it’s made until the time you install it, your hose will be protected. That means your equipment will be protected too.